PLC & Scada Workshop

Programmable Logic Controller or PLC is a computing system used to control electromechanical processes.

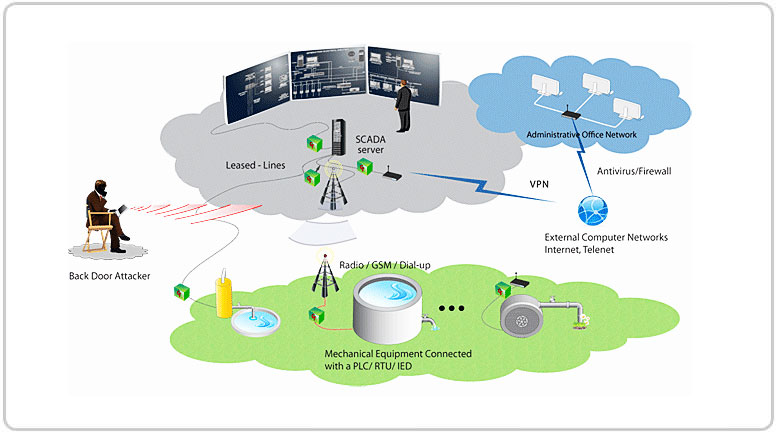

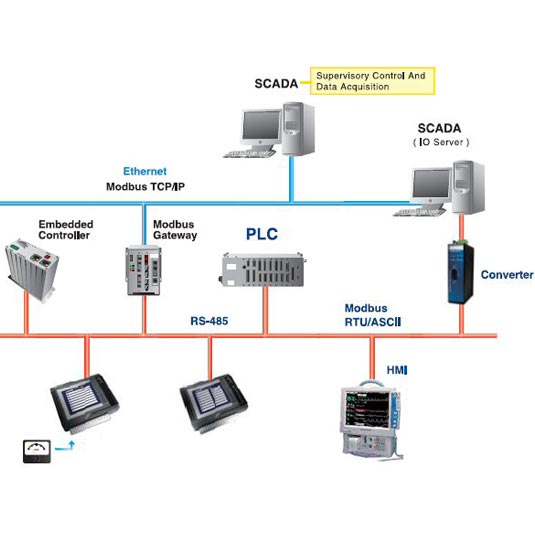

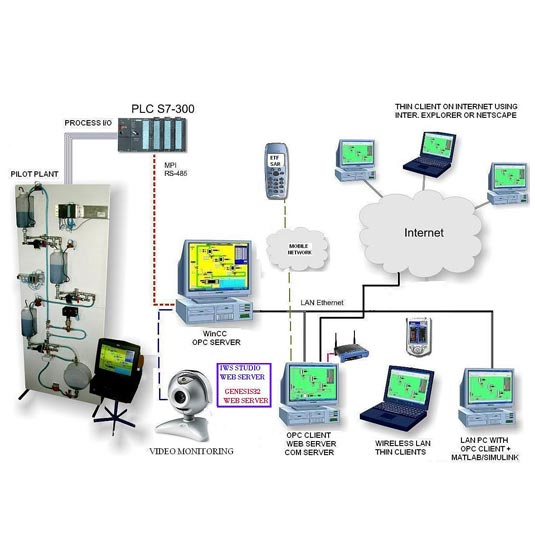

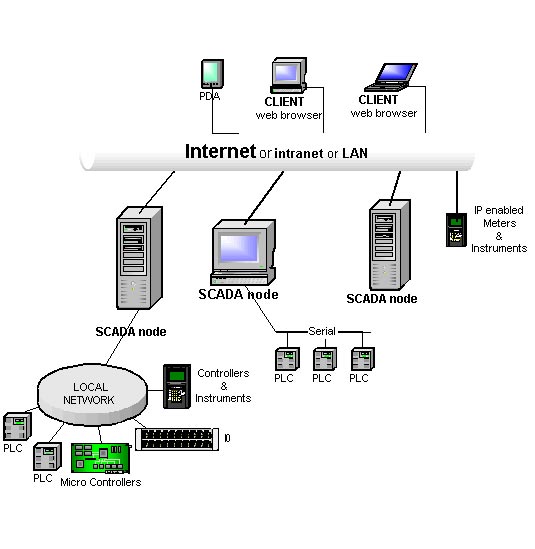

SCADA stands for Supervisory Control and Data Acquisition. It is a type of industrial control system that is used to monitor and control facilities and infrastructure in industries.

Project Description

- Overview

- Course

- Project

- Kit

- Photo Gallery

- Video Gallery

OVERVIEW

The Most Used Guiding Force Behind An Automated Industrial Plant Is A "Programmable Logic Controller" Generally Known As A PLC. PLCs Along With Certain Other Necessary Ingredients Like Sensors, Motors, Actuators, Valves, Conveyors, Boilers, SCADA Systems, Computers & Many More, Makes A Real Automated Manufacturing Plant.

The main objective of PLC & Scada Workshop is to make the aspiring engineers acquainted with the conceptual as well as practical knowledge of the Industrial Automation & latest technologies being used to achieve industrial automation. The idea of organizing this workshop is to inculcate the basic fundamentals of automation in the students and provide them with a platform to work on, In The Near Future.

Workshop Level : Intermediate Level

Best Suited for: All B.Tech/B.E./BCA/BSc Students

Workshop Certification: Robosapiens Technologies Pvt. Ltd.

Kits Source :

Day 1 (Session 1)

Presentation on Recent Trends in Industrial Automation & PLC-SCADA

- Introduction To Automation

- Why We Need Automation

- Evolution In Industrial Automation (A Brief History)

- Different Type Of Industrial Control Mechanisms)

- Introduction to PLCs

- PLC Advantages over Microcontrollers

- Area of Applications

- DATA Flow During Automation

- Motor Drives Introduction & Their Need

- Sensors Introduction & Their Need

- HMI Introduction & Its Need

- SCADA Introduction& Its

Day 1 (Session 2)

Detail study of PLC & SCADA

- PLC

- SCADA

PLC I/Os Basics, Burning & Interfacing Concepts

- Allen Bradley & Rockwell Automation's Details

- Brief Description To Input/ Output Pins Of Micrologix-1000

- Ladder Diagram Basics

- Introduction To RSLogix

- Downloading a Ladder Program in PLC Using RSLinx.

- How To Take Input from Panel

- How To Give Output To Panel

- Running First PLC Application

Day 2 (Session 3)

Hands on PLC Training Kit & SCADA Software

- Participants will perform hands on PLC training Kit which contain Allen Bradley Micrologix 1000 PLC.

- Software Used: RsLogix, RsLinx & Wonderware InTouch(SCADA)

Day 2 (Session 4)

Zonal Competition

After the hand on theory and practical experience from the workshop, Zonal Round Competition will be conducted for the participants.

Certificate Distribution

On behalf of Robosapiens Technologies Pvt. Ltd. Certificate of Merit will be provided to all Zonal Round Winners and Certificate of Participation will be provided to all the Zonal Round Participants (Excluding Merit Participants).

Project to be Covered

- Electronics and Communication Engineering

- Computer Keyboard Controlled Robot

- Electronics and Computer Engineering

- Electronics and Instrumentation Engineering

1x X-Bee Trainer Board with Atmega 16/32 Version 2

- Programming via boot loading through USB Port or 6-Pin ISP (In System Programming) cable.

- Driver Software not required (Plug & Play device).

- Three ports available for user interface: PORTA, PORTB, PORTC, PORTD

- External Reset Switch

- On board crystal oscillator of 12 MHz frequency.

- On board LCD interface port.HXD® BUZZER for audible interaction with the users.

- Dedicated DTMF decoder IC module plug-in slot.

- Two supply inputs: One through battery and Second through Adapter.

- On board 5 volt regulated power supply for the board and external peripherals.

- On board X-Bee Interface.

- Two H-Bridge implemented on the board using L293D IC to drive two DC motor with 1A drive current at voltages 4.5 to 36 volt.

1x ( ATmega16 with inbuilt Robosapiens Bootloader )

1x X-Bee Explorer

2x X-Bee wireless Module ( S2 Series )

1x ( USB Connector cable )

1x LCD 16x2

1x ( High Quality Plastic Chassis Board )

1x ( Screw driver )

1x ( Metal Ball Caster wheel )

4x ( Support Studs

1 Pair wheel 76mm Diameter

1 Pair D.C Plastic gear motors

Other required Tools and accessories etc.

Photo Gallery

Video Gallery

Workshop Highlights

- High Quality practical/ application oriented training

- Industry accepted course content

- Regular home assignments

- Alternate week theory & lab exams

- Well qualified Faculties having rich industry background

- Technical Mock Interviews

Attractions

- To Increase Labor Productivity

- To Improve Worker Safety 6. To Improve Product Quality

- To Reduce Labor Cost

- To Reduce Manufacturing Lead Time

- To Avoid The High Cost Of Not Automating

- To Reduce Or Remove Routine Manual And Clerical Tasks

- To Mitigate The Effects Of Labor Shortages

- To Accomplish What Cannot Be Done Manually